Aluminum composite panel is a building material consisting of two aluminum sheets and a combination of low-density polyethylene filling between them. Adhesive granule and polyethylene adhesion to aluminum plate is provided. Because the top aluminum plate is painted, it has superior surface strength. In our composite panels; lightness, aesthetic appearance, fast and easy installation, high sound and heat insulation, a wide variety of colors and flexible project applicability are the most obvious features.

Aluminum Composite Panel

Our products are produced in three types: B2 standard type, non-combustible A2 and B1-FR (Flame Retardant) aluminum composite panels. Our flame-retardant and flame-resistant products have Exova and WarringtonFire test approval reports. Our Alutechbond aluminum composite panels also have ERA, TSE, G conformity certificate, TSE National Technical approval, ISO 9001, ISO 14001, ISO 27001 Information Security Management, Gost-R, Russia Fire, ITP Poland certificates.

With our ALUTECHBOND® 100/200/300/400 series composite panel products that add color to the building world, we offer our customers unlimited color and texture options that provide creative architectural solutions.

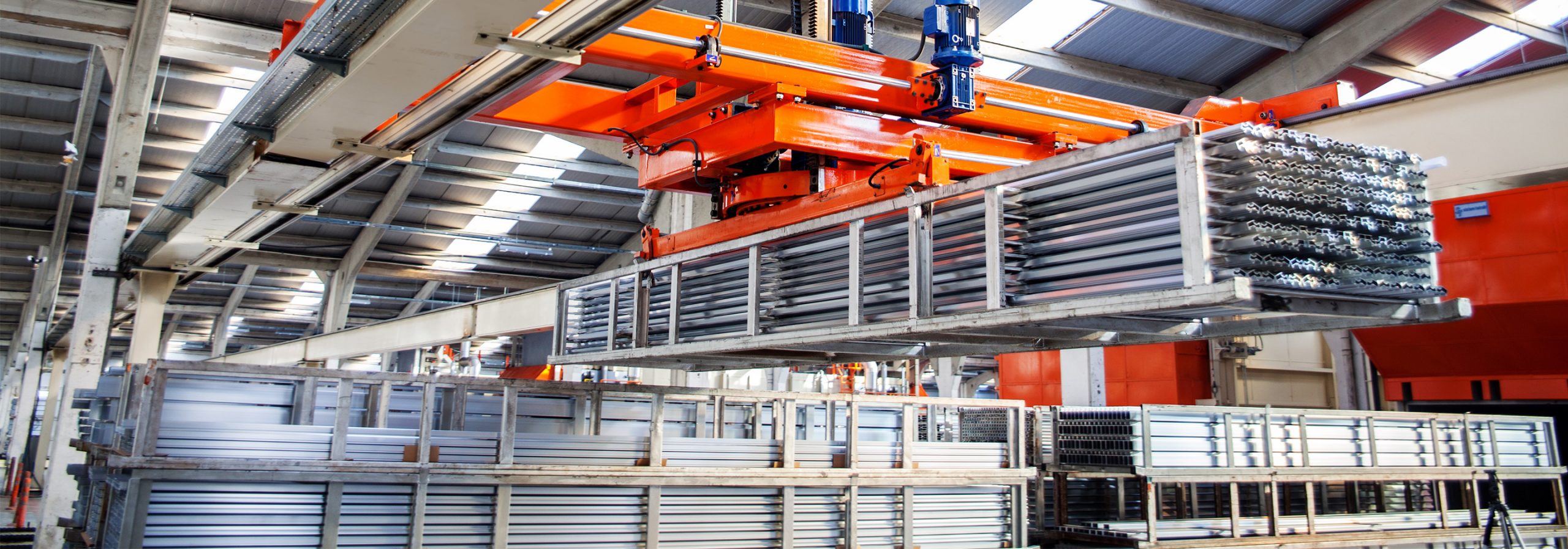

ALUTECHBOND® aluminum composite panels can be used at temperatures from -50 °C to +80 °C and the warranty period is 20 years. Building interior and exterior facades, decoration applications, billboards are the main areas of panel use. All materials used in the production of composite panels are recyclable. The annual total capacity of our three composite panel lines, which we produce from 0.21, 0.30, 0.35, 0.40- and 0.50 mm thickness range and 1,250- and 1,500 mm wide x 3,200 mm length plates, has reached 9.000.000 m2.